Cytocompatible, Transparent, and Clickable

Resin for 3D Printing.

Warrick Ma & Yadong Wang

The synthesis of biocompatible, acrylate-free 3D printing resins that is based on a ABA triblobk copolyester.

EU parliament voted to phase out animal testing in 2021. In ths US, FDA commits to explore alternative methods that will replace animal testing in drug development. Organ-on-a-chip is a promising alternative because it mimics human physiology well in a highly controlled in vivo environment. Current fabrication of organ-on-a-chip, however, has poor z resolution, and is impractical to be automated to meet the increasing demand. Further, it almost exclusiively uses polydimethylsiloxane (PDMS). Although PDMS is biocompatible, its hydrophobicity and chemical inertness make it incompatible with many small-molecule test compounds and extrmemely difficult to functionalize.

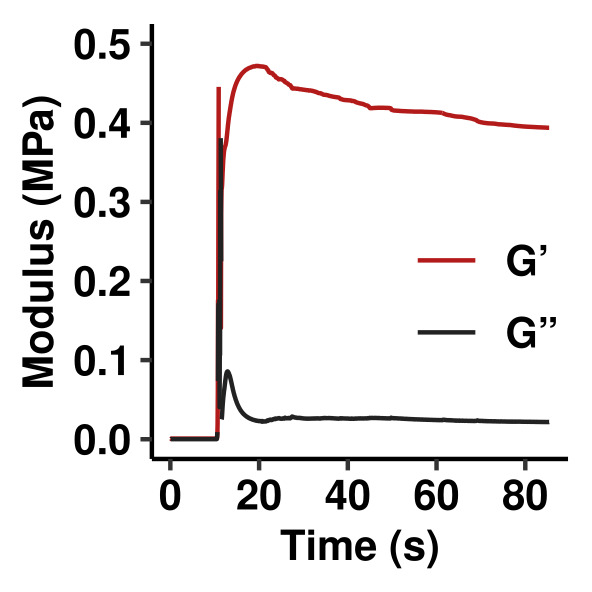

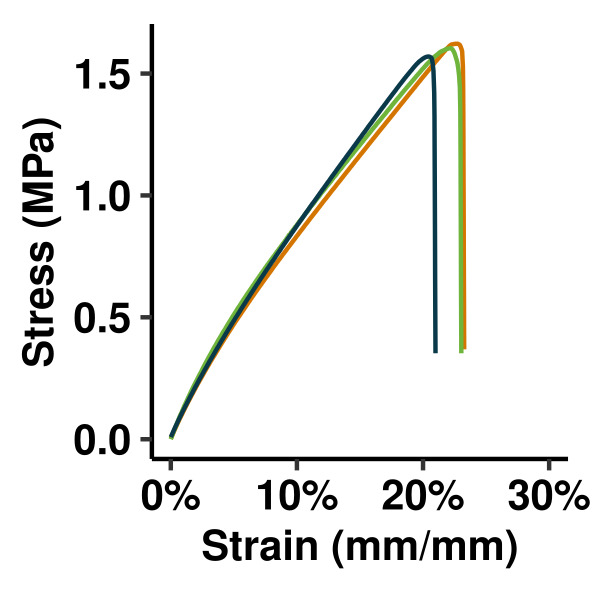

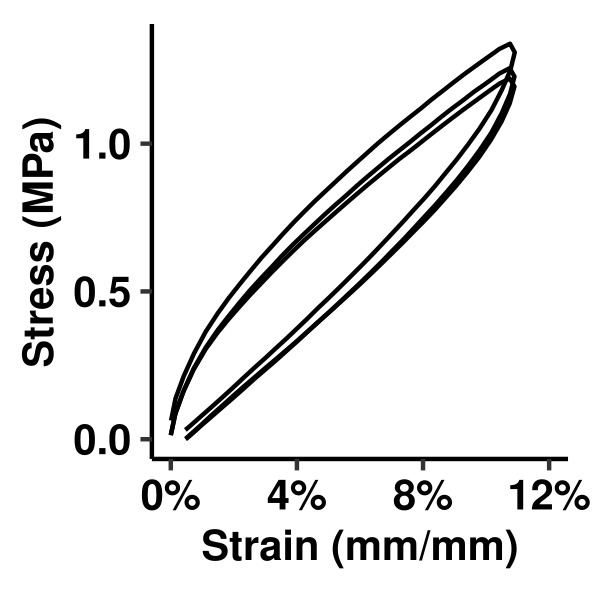

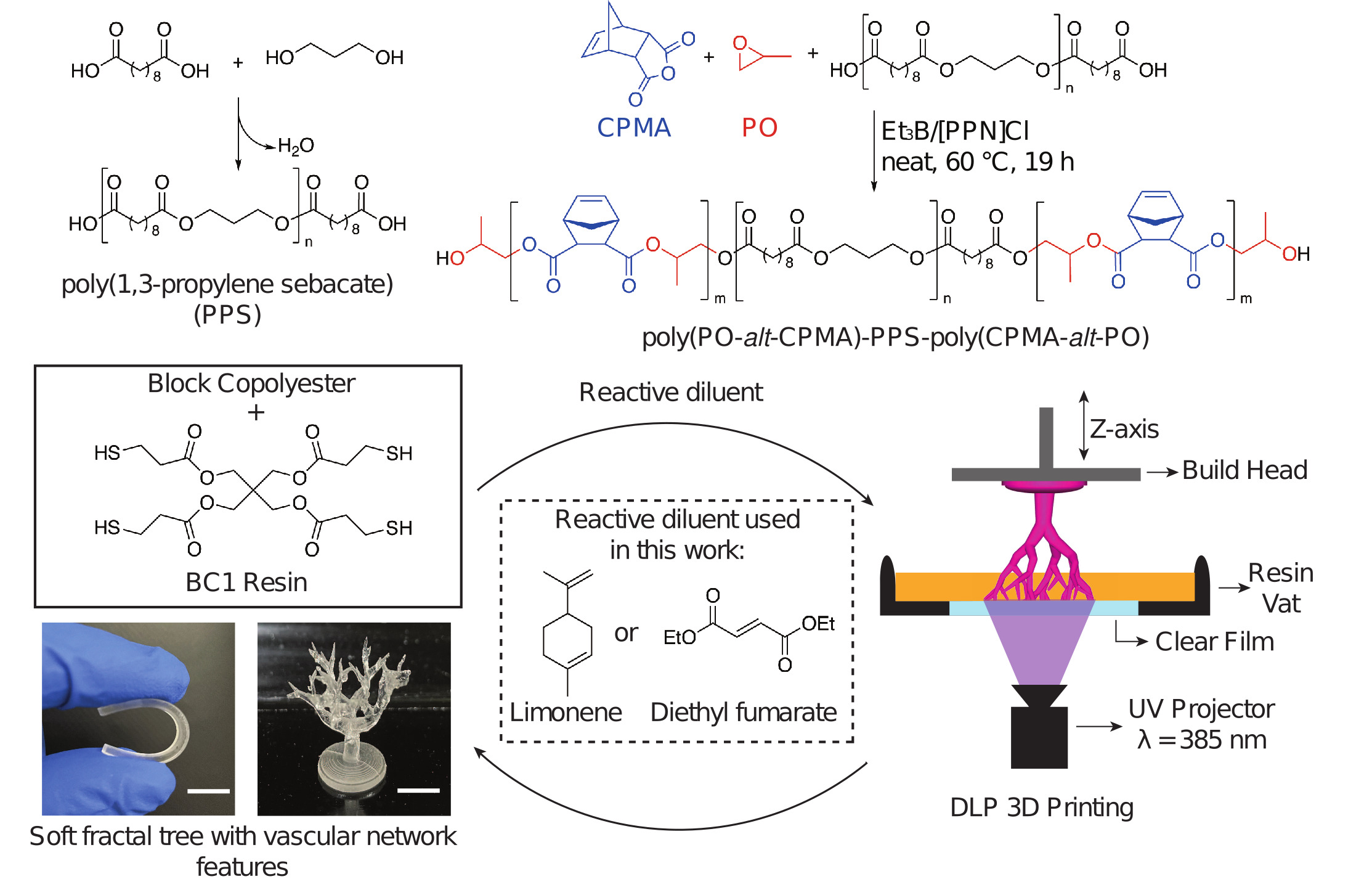

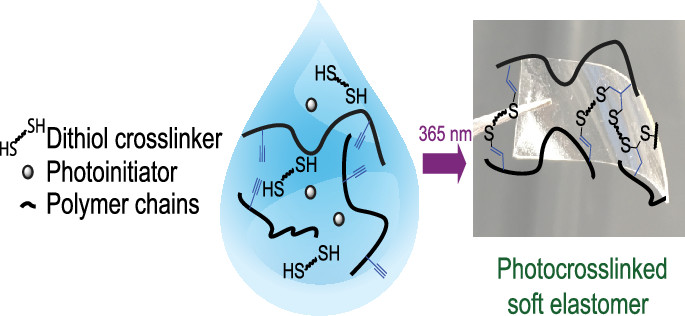

3D printing can revolutionize organ-on-a-chip fabrication by enabling automated production of 3D objects with highly complex features. Unfortunately,the current market is saturated with acrylate-based resins with poor biocompatibility. Acrylates attack DNA and proteins, therefore decimating in vitro cell populations in a few hours. Thiol-ene photopolymers are acrylate-free. We thereby synthesized photopolymers via ring-opening copolymerization (ROCOP) of propylene epoxide, norborene anhydride (CPMA), and a custom chain transfer agent (CTA). The triblock architechture allows us to tune the mechnical properties by adjusting the length of each block.

Currently, I am applying for Ignite Fellow for New Ventures at Cornell University. The goal of the program is to build strong high-value new businesses, grow entrepreneur scientists and engineers, advance technology commercialization, and enrich Cornell’s venture ecosystem. This program will give me the necessary funding and network to explore the commercial prospects of my invention. ROCOP's compatibility with many CTAs will afford mateirals with tunable mechanical and physical properties, thus allowing me to target different market segments and applications. I envision my invention to not only penetrate the organ-on-a-chip market, but provide versatile biocomaptible resins to the broader biomedical engineering community.

Warrick Ma & Yadong Wang

Warrick Ma, Xiaochu Ding, Ying Chen & Yadong Wang

I have developed automated workflows to plot mechanical testing data in R. Check out my Github for more!